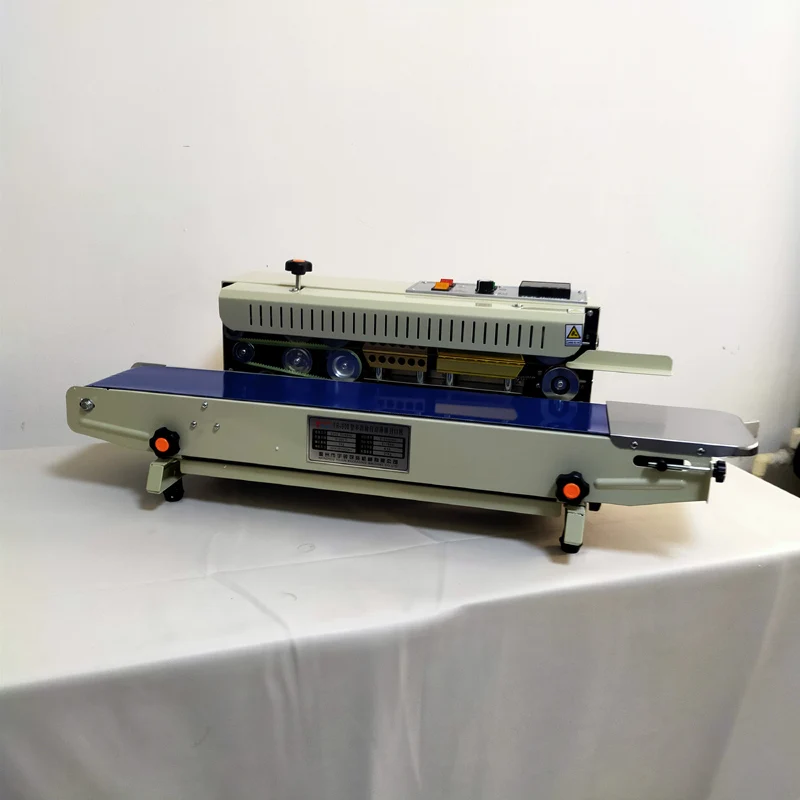

Snack Food Pouch Plastic Bags Band Sealer

1,645.00$ – 1,919.00$

Band Sealer

Application

From medicine, agricultural chemicals, food, date, lubricating oil aluminum foil bags, the plastic bag, compound bag ideal seal machinery.

Character

This sealing machine is according to the domestic and foreign advanced type foundation in, the redesign manufacture becomes, but also has stands lies function of the dual purpose seal. Is suitable in all plastic film seal and the system bag, is unit’s and so on food products factory, cosmetics factory, pharmaceutical factory ideal seal equipment, but continuous working, but also may need to split out the date, the batch number according to the user and so on .Is suitable forms a complete set in the assembly line.

|

Model |

FRB-770H |

FRB-770V |

FRB-770V-PLUS |

FRB-770V-MAX |

|

Working way |

Horizontal |

Vertical |

Vertical |

Vertical |

|

Frame option |

Paint |

Paint |

Paint |

Paint |

|

Date option |

Stamping |

Stamping |

Stamping |

Stamping |

|

Air option |

– |

– |

– |

– |

|

Bag Height |

– |

150-270mm |

280-500mm |

100-750mm |

|

Sealing length |

Unlimited |

Unlimited |

Unlimited |

Unlimited |

|

Loaded weight |

< 3kg |

< 5kg |

< 15kg |

< 50kg |

|

Sealing temperature |

0-300°C |

0-300°C |

0-300°C |

0-400°C |

|

Seal capacity |

1-16m/min |

1-16m/min |

1-16m/min |

1-10m/min |

|

Seal Width |

10mm |

10mm |

10mm |

12mm |

|

Seal thickness |

0.02-0.08mm |

0.02-0.08mm |

0.02-0.08mm |

0.02-0.08mm |

|

Electric |

220V/110V |

220V/110V |

220V/110V |

220V/110V |

|

Power |

600w |

700w |

700w |

900w |

|

Dimension |

840x380x320 |

850x400x450 |

850x400x600 |

1430x680x1480 |

|

weight |

24kg |

28kg |

36kg |

130kg |

|

Model |

FRB-770H |

FRB-770V |

FRB-770V-PLUS |

FRB-770V-MAX |

|

Working way |

Horizontal |

Vertical |

Vertical |

Vertical |

|

Frame option |

Paint |

Paint |

Paint |

Paint |

|

Date option |

Stamping |

Stamping |

Stamping |

Stamping |

|

Air option |

– |

– |

– |

– |

|

Bag Height |

– |

150-270mm |

280-500mm |

150-600mm |

|

Sealing length |

Unlimited |

Unlimited |

Unlimited |

Unlimited |

|

Loaded weight |

< 3kg |

< 5kg |

< 15kg |

< 50kg |

|

Sealing temperature |

0-300°C |

0-300°C |

0-300°C |

0-400°C |

|

Seal capacity |

1-16m/min |

1-16m/min |

1-16m/min |

1-10m/min |

|

Seal Width |

10mm |

10mm |

10mm |

12mm |

|

Seal thickness |

0.02-0.08mm |

0.02-0.08mm |

0.02-0.08mm |

0.02-0.08mm |

|

Electric |

220V/110V |

220V/110V |

220V/110V |

220V/110V |

|

Power |

600w |

700w |

700w |

900w |

|

Dimension |

840x380x320 |

850x400x450 |

850x400x600 |

1430x680x1480 |

|

weight |

24kg |

28kg |

36kg |

130kg |

Soft Tube Filling and Sealing Machine

For plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food and chemical…

Materials application

Soft tube filling and sealing machine has the advantages of reasonable structure, uniform functions, convenient operation, accurate loading, stable operation and low noise. The PLC programmable controller is used to program the whole machine, from liquid to high viscosity fluid material (paste) for filling and sealing to code number (including production date) and other processes. It is an ideal equipment for filling and sealing aluminum tubes, plastic tubes and composite tubes in cosmetics, pharmaceuticals, food, adhesives and other industries, and meets GMP requirements.

Paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc.

Advantages

High-grade LCD display programming controller and button combined operation screen, fully grasp the equipment’s sleepless speed regulation, parameter equipment, production count statistics, air pressure indication, fault display and other operating conditions, making the operation simple and user-friendly.

Fully complete the whole process of human supply pipe, benchmarking, filling inert temperature body (optional), filling, sealing, coding, and finished product export.

High-precision benchmarking system reduces the range of color difference between the tube and the color scale.

External adjustment position and digital display of position, quick and accurate adjustment (suitable for multi-species, multi-species production).

Machine, light, electricity and gas integration, no tube is not filled, the tube is not in place, low pressure, automatic display (alarm); automatic function such as automatic shutdown when opening the protective door.

Technique Performance

|

Model |

TFS-250S |

TFS-250A |

TFS-250AH |

|

Automation |

Semi-auto |

Automatic |

Automatic |

|

Power |

2kw |

4kw |

4kw |

|

Voltage |

220V 50hz |

220V 50hz |

220V 50hz |

|

Sealing |

10-50mm |

10-50mm |

10-50mm |

|

Tube Height |

10-250mm |

20-250mm |

45-250mm |

|

Air pressure |

0.6Mpa |

0.6-0.8Mpa |

0.5-0.65Mpa |

|

Filling Range |

3-30ml |

3-30ml |

3-30ml |

|

Capacity |

20-30 |

25-60 |

60-80 |

|

Dimension |

1100*800*1600mm |

1600*800*1830mm |

2500*1200*2400 |

|

Weight |

300kg |

700kg |

1500kg |

Automatic Bottle Capping Machine

An automatic bottle capping machine is a hightech equipment used in the packaging industry to automatically seal bottles with various types of caps. It is versatile, capable of handling different cap and bottle sizes, and production speeds. The machine operates with precision, reducing human error and optimizing efficiency. It also features quality control features to ensure proper sealing and product integrity.

CAP APPLICATIONS

Different cap application methods are available for sealing bottles based on their specific design. Screw caps are the most widely used type and are screwed onto bottles with threaded necks. Snap-on caps snap onto the bottle neck, while push-on caps are pushed onto the neck of the bottle. Crimp caps require a crimping tool and are commonly used in the pharmaceutical industry. Corks are typically used for wine bottles and require a corking machine for insertion. ROPP caps are frequently used in the beverage industry and involve rolling the cap onto the neck of the bottle with a specialized machine. Trigger caps are commonly used in the household and automotive industries and require a capping machine with a specialized trigger capping head.

|

Model |

XGJ-CG-S |

XGJ-CG-TB |

XGJ-CG |

XGJ-ROPP |

|

Type |

Semi-auto |

Table top |

Vertical |

Vertical |

|

Voltage |

220V |

220V |

220V |

220V |

|

Bottle height |

30-280mm |

30-300mm |

38-200mm |

180-320mm |

|

Bottle diameter |

– |

– |

35-140mm |

40-140mm |

|

Cap diameter |

20-70mm |

19-65mm |

15-60mm |

22-32mm |

|

Speed |

20-45 B/Min |

25-50 B/Min |

20-50 B/Min |

30-70 B/Min |

|

Power |

0.6kw |

0.8kw |

1.5kw |

1.7kw |

|

Weight |

40kg |

80kg |

250kg |

350kg |

|

Size(mm) |

500*380*700 |

1050*620*880 |

2000*700*1600 |

2000*890*1900 |

Automatic Can Sealing Machine

For Can Canister bottle sealing.

Application

This fully-automatic can sealing equipped with 4 rollers can achieve double seam via 2 operations to avoid leakage.

Ideal for sealing tuna, sardine & other cannery food in the tin, aluminum, Fer rum and other round metal cans.

Suitable for packaging in food, beverage, leisure food, pharmaceutical and chemical industries etc, such as nuts, preserved fruits, Chinese herbal, etc.

Description

High volume Fully-automatic single head sealer

4 rollers for consistent & leak-proof seam

Perfect for sealing tin, aluminum, PET& other paper cans with a maximum diameter of 130mm

Adopts PLC and man-machine interface are integrated and controlled by microcomputer technology, which realizes human-machine data exchange, and is easy to operate and intelligent.

Overload protection system avoided machine overload damage,provides a smarter using experience while extending the life of your equipment and saving on maintenance costs.

Whole sealing head and lifting tray are made of 304# stainless steel.At the same time of rust prevention, the mechanical rigidity is better, and the sealing effect is better and more stable.

The electrical components are all internationally renowned brands, which make the equipment run more stable, the service life is extended, the maintenance cost is saved, the replacement is more convenient and quick, and the customer can purchase and use it locally.

Seal without Leakage

Double Seam

All our automatic can sealers are equipped with 4 rollers, which can achieve an airtight double seam, a strong mechanical structure containing 5 layers of metal.

Strong Rollers

By improving the rigidity of the rollers, our can sealing machine can form a stronger hermetic seal, ensuring that every can of your product is leakage-free.

Perfectly-matched Too-lings

Too-lings of every can sealer are exclusively-made based on the size & type of your can. So the lid is perfectly sealed to the can body without any gap for leakage.

Technical parameter

|

Model |

CS |

|

Sealing head qty |

1 piece |

|

Seaming roller |

4pcs |

|

Speed |

35-50pcs/min |

|

Can height |

20-200mm |

|

Can diameter |

35-130mm |

|

operating temperature |

0~45℃ |

|

Working power supply |

three phrase |

|

Total power |

2050W |

|

Air pressure |

0.5-0.6MPA |

|

Weight |

380kg |

|

Size |

2950(L)*950(W)*1700(H)mm |

Twist Tie Packing Machine

Without direct power supply ,yet only need a little compressed air and manpower to finish all pneumatic control ,performances reliable and bags beautiful ,it is an ideal selection for making flower for bread bags and candy bags…

Characters

Pneumatic type Tying Machine Tying with color wire

Pan Shaping for Upper Bag margin show nice outlook

Without electricity supplying, it works by compressed air and various thickness of wires are available

No need the electricity for the operation. But it’s driven by compressed air

Easy to replace the fan shaping folder and good to make fan shape

Various thickness of wires are available Dust remover is available as an option in the dusty place. It helps to extend machine’s lifespan.

Technical specification

|

Model |

Frame |

Max. Bag Width |

Capacity |

Rope Length |

Air Pressure |

Weight |

Dimension |

|

TIE-250 |

paint |

250 |

30-40 |

100 |

0.4-0.6 |

35 |

600x600x1000 |

|

TIE-300 |

stainless steel |

300 |

30-40 |

100 |

0.4-0.6 |

45 |

700x600x800 |

|

TIE-400 |

stainless steel |

400 |

30-40 |

100 |

0.5-0.6 |

45 |

700x600x800 |

window.adminAccountId=221016274;

Specification: Snack Food Pouch Plastic Bags Band Sealer

|

||||||||||||||||||||||||||

| Dimensions | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||

User Reviews

Be the first to review “Snack Food Pouch Plastic Bags Band Sealer”

1,645.00$ – 1,919.00$

There are no reviews yet.